- HOME

- >

- Online shopping

- >

- Equipment

- >

- CNC Milling Machines

- >

- Roland CNC Machines

- > MDX-50 CNC milling machine

Online shopping

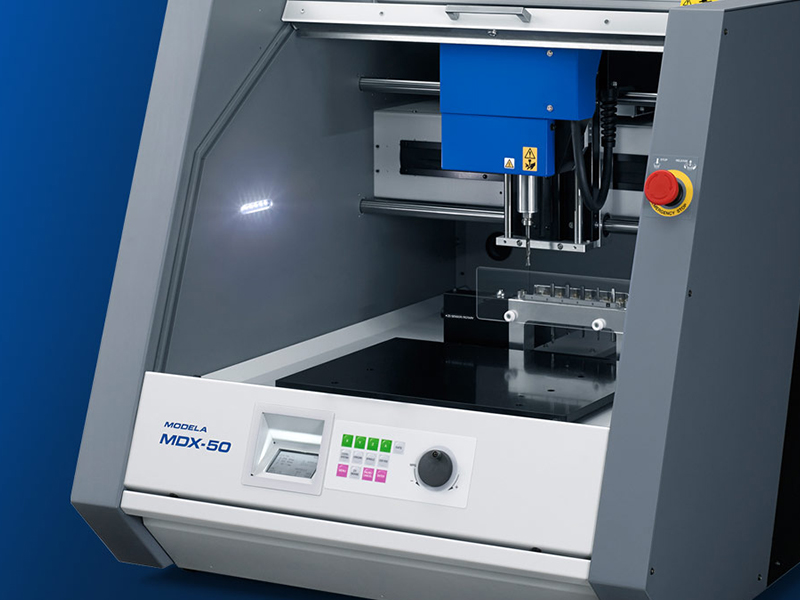

MDX-50 CNC Milling Machine

The MDX-50 benchtop CNC mill combines precise, automated milling and unmatched ease-of-use. An ideal solution for short-runs and prototypes, the MDX-50 reduces operation time and simplifies production.

MDX-50 Key features:

.Desktop CNC rapid propotyping equipment

.Automatic Tool Changer-Continuous operation, no need to stop work for tool change

.A machining area of 15.8"(400mm)(X) x 12"(305mm)(Y) x 5.3"(135mm)(Z)

.Optimized drive system can support the stereo stability of the device

.SRP Player CAM

.Optional rotary axis, self-centering headstock and tailstock workpiece clamps

The MDX-50 benchtop CNC mill combines precise, automated milling and unmatched ease-of-use. An ideal solution for short-runs and prototypes, the MDX-50 reduces operation time and simplifies production.

MDX-50 Key features:

.Desktop CNC rapid propotyping equipment

.Automatic Tool Changer-Continuous operation, no need to stop work for tool change

.A machining area of 15.8"(400mm)(X) x 12"(305mm)(Y) x 5.3"(135mm)(Z)

.Optimized drive system can support the stereo stability of the device

.SRP Player CAM

.Optional rotary axis, self-centering headstock and tailstock workpiece clamps

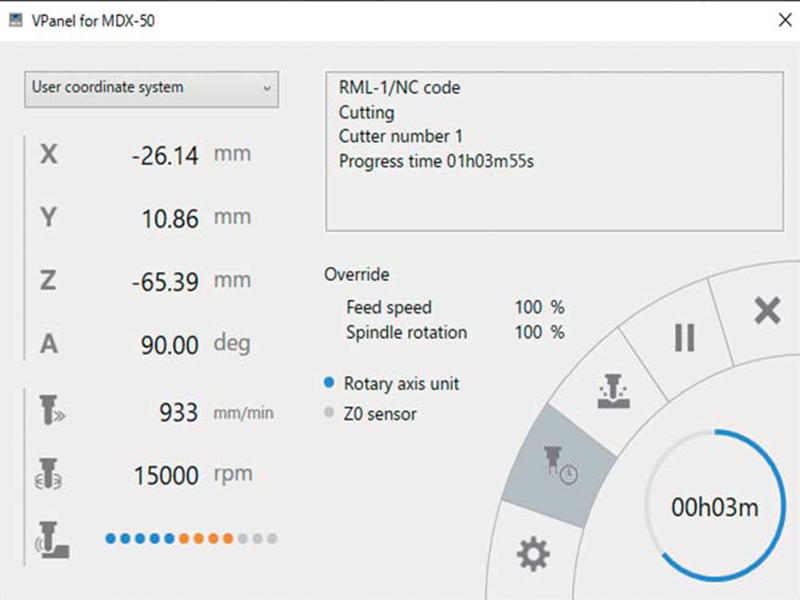

Operator-Friendly Control and Software

Become a 3D milling expert almost immediately with the MDX-50's simple yet powerful built-in control panel and virtual control panel (VPanel), and bundled SRP Player CAM software that's easy-to-use and simplifies operation. With the control panel at the front of the unit, almost all operations can be completed from the unit itself without having to go back to a PC. The VPanel interface operates seamlessly with the MDX-50 and allows users to make changes to spindle rotation or speed during operation.

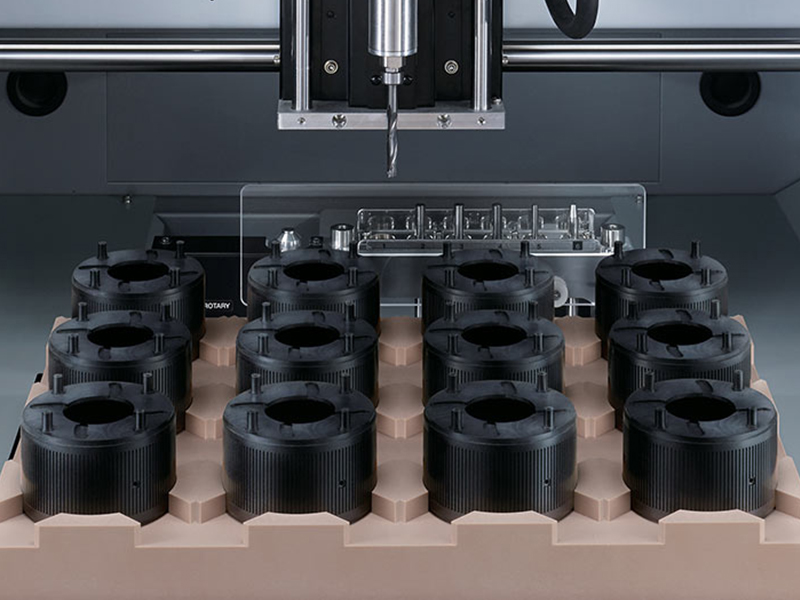

Automatic Tool Changer

The MDX-50 increases performance with an expanded machining area and increased operating speeds, while reducing production time with faster job processing and a 5-station Automatic Tool Changer for continuous operation without stopping to change milling tools. The materials used commonly of MDX-50 desktop CNC Miller are: ABS、POM、Nylon plastic foam、Wax model、PVC plywood, hardwood, acetal plastic.

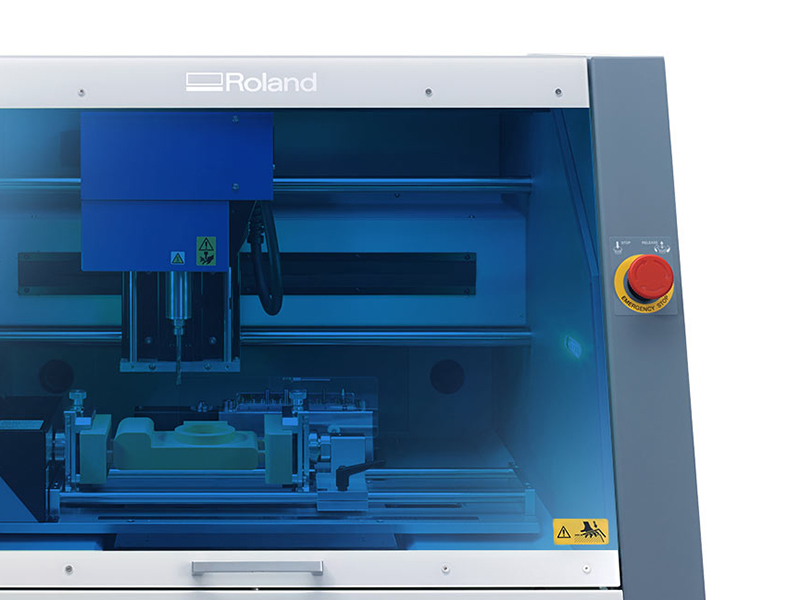

Mill Fine Details and Smooth Finishes

With an improved drive system, machine rigidity and enhanced drive mechanics, the MDX-50 mills incredibly smooth and accurate prototypes for testing structure, function, and assembly with other parts. A machining area of 15.8”(400mm) (X) x 12”(305mm) (Y) x 5.3”(135mm) (Z) supports production of large single objects or batch production of smaller multiple parts.

Other Distinguishing Features

.Advanced drive system supports dimensional stability

.Large machining area plus enhanced machine rigidity and drive mechanics

.Optional Rotary Axis with self-centering headstock and tailstock workpiece clamps

.Requires no special electrical set-up and needs no additional air compressor

.Multi color-coded LED status light notifications and email notifications inform users of machine status

.Built-in debris collection drawer with rail guided safety door for safe and clean production

.Ideal for use in studio and educational environments

Automatic Tool Changer & Optional rotary axis

Auto-sensing function corrects the tool length to ensure milling accuracy for every job. Optional rotary axis for effortless production of complex surfaces, includes a wide, self-centering headstock and tailstock workpiece clamps. Auto-rotates materials from 0-to-360 degrees, indexes for 2-sided, 4-sided and custom angles.

Simplified Machine Set-up

The MDX-50 reduces the time and effort of machine ste-up with an expanded work area, inner-machine lighting for clear visibility, and an included tool adapter that enables instant installation of ATC tools-requiring no wrench or addition tools.

Safe, Clean, and Convenient Production

The MDX-50 is designed for use in studio and educational environments. A newly improved door ensures extra-safe operation while waste is contained in a built-in debris collection drawer.

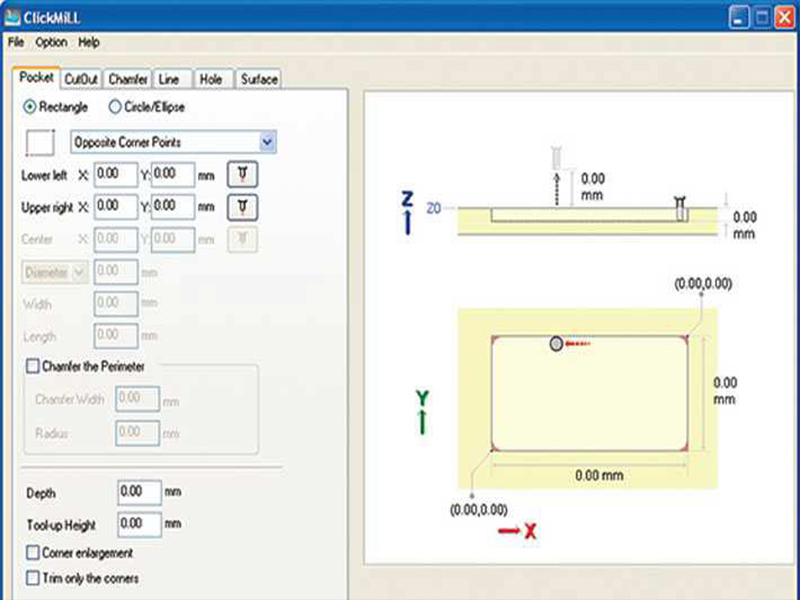

SRP Player CAM

The popular in Industry and Education software has been updated to match the advanced functions of the MDX-50. Milling settings can be configured in five simple steps, making operation straightforward even for those new to milling. ClickMill ClickMill Software provides direct control of the MDX-50 for surfacing, drilling holes, cutting pockets and other finishing processes, all without having to access CAD or CAM software.

Virtual Control Panel (VPanel)

VPanel serves as a computer-based virtual control panel with all of the functionality of the physical on-board control panel, as well as tool life management and e-mail alerts.

Roland has obtained international ISO certification, which is a recognition of Roland's high-quality products and excellent service. The product also enjoys a one-year warranty.

| MODEL | MDX-50 | |

| Acceptable materials* | Resins such as chemical wood and modeling wax (metal not supported) | |

| Operating range | X: 15.80in (400mm) Y: 12.00in (305mm) Z: 5.315in (135mm) |

|

| Table size | W: 15.80in (400mm) D: 12.00in (305mm) |

|

| Loadable workpiece size | X: 15.80in (400mm) Y: 12.00in (305mm) Z: 3.90in (100mm) |

|

| Axis drive | Stepper Motor | |

| Feed rate | XY: 0.3in to 141.7 in/min (7 to 3600mm/min) Z: 0.3 to 118.1 in/min (7 to 3000 mm/min) |

|

| Software resolution | RML-1: 0.001 mm/step NC code: 0.001 mm/step | |

| Mechanical resolution | 0.01 mm/step (0.39 mil/step; half step) |

|

| Spindle motor | Brushless DC motor | |

| Spindle rotation speed | 4500 ~ 15000 rpm | |

| Tool chuck | Collet | |

| Tool Change Method | AutomaticTool Changer (ATC) | |

| ATC Magazine Capacity | 5 Tools + 1 Detection pin (6 Position Capacity) | |

| Tool Shank Diameter | 0.250in, 0.125in (6.35, 3.175mm) |

|

| Operating noise | During operation | |

| Dust box dimmensions | 23.62 x 27.65 x 3.74in (600 x 700 x 95mm) |

|

| Interface | USB | |

| Power requirements (VAC/A) | AC 100 to 240 V ±10%, 50/60 Hz, 1.2 A (Overvoltage Category: II, IEC 60664-1) |

|

| Power consumption (W) | ≈ 95W | |

| Acoustic noise level (dB) | No-load operation: | 60 dB (A) or less |

| Standby: | 45 dB (A) or less | |

| External Dimensions | Width X Depth x Height: | 29.92 × 35.43 × 28.82 in (760 × 900 × 732 mm ) |

| Weight | 269lb (122kg) | |

| Installation environment | Indoor use at altitudes | Up to 6500ft (2000 m) |

| Temperature | 41 to 104°F (5 to 40°C) | |

| Humidity | 35 to 80%RH (no condensation) | |

| Ambient pollution degree | 2 (as specified by IEC 60664-1) | |

| Short-term temporary overvoltage | 1440 V | |

| Long-term temporary overvoltage | 490 V | |

| Included items | Power cord, USB cable, manual, Roland DG Software Package CD, detection pin, hexagonal screwdriver, hexagonal wrench, wrench, tool holder, tool positioner, Z0 sensor |

|

side2_mod_top

side2_mod_bottom